Comparison of organic fertilizer production lines and bio-organic fertilizer production lines

Organic fertilizer production lines mainly handle the safe processing of organic waste like livestock manure and crop stalks. Bio-organic fertilizer production lines add a functional microbe inoculation step to this process. Beneficial microbes like Bacillus subtilis or Bacillus amyloliquefaciens are typically added late in fermentation or before granulation. This gives the final product both organic matter and biological activity.

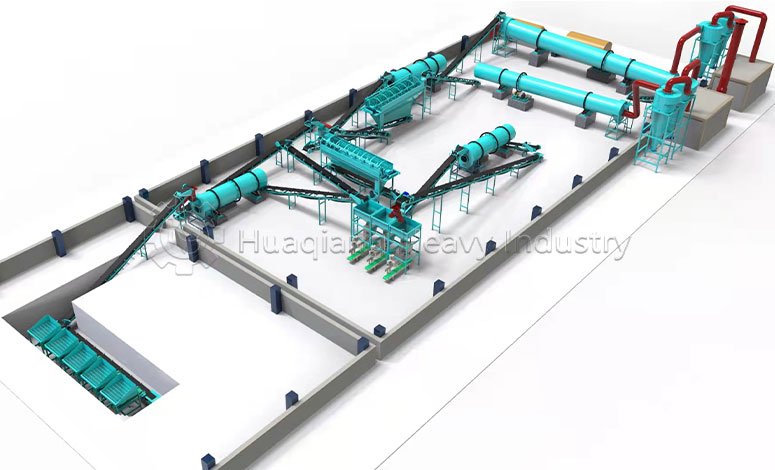

1.Equipment Differences

The core equipment (crushers, compost turning machines, granulators) is mostly the same for both lines. However, bio-organic lines must have a dedicated system for mixing in the microbial agents and low-temperature drying equipment (temperatures need to be kept below 50°C).

2.Product Value

Standard organic fertilizer primarily provides organic matter (≥30%) and some basic nutrients (NPK). Because bio-organic fertilizer contains ≥200 million viable microbes per gram, it also improves soil health and suppresses plant diseases.

3.Return on Investment

Setting up a 10,000-ton-per-year organic fertilizer line costs roughly ¥800,000 – ¥1.2 million. A bio-organic line of the same scale costs ¥1.5 – ¥2 million (mainly due to adding microbe culturing and testing equipment). But profit-wise: bio-organic fertilizer can have a gross profit margin of 40-50%.

4.Recommendations

If a company mainly processes farm manure and targets regular field crops, an organic fertilizer line offers better value. If the company has access to specific microbial strains or focuses on high-value cash crops, investing in a bio-organic line is advisable.

Whether traditional organic or bio-organic, the core goal is turning agricultural waste into a resource. Companies should choose based on their budget, technical capabilities, and market access.