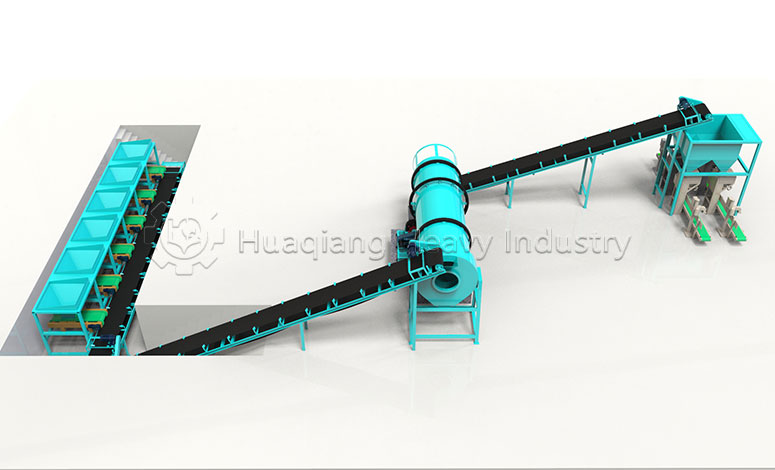

Complete breakdown of NPK blending fertilizer production line process

The NPK blending fertilizer production line plays a vital role in fertilizer manufacturing, featuring a scientific and efficient process. Here’s the step-by-step workflow:

- Raw Material Supply

The process begins with receiving raw materials. Nitrogen (N), phosphorus (P), and potassium (K) sources like urea, monoammonium phosphate, and potassium chloride are delivered to the facility. Initial quality checks and precise weighing ensure materials meet standards and quantities.

- Proportioning

Next comes precise ingredient measurement. High-precision dosing equipment measures raw materials according to predetermined NPK ratios. Advanced automated control systems minimize deviations, guaranteeing accurate nutrient composition.

- Mixing

The measured materials then enter industrial fertilizer mixer machines. Using unique stirring mechanisms, these machines thoroughly blend different particles to create uniform fertilizer batches. Proper mixing duration and intensity ensure consistent NPK distribution in every product unit.

- Packaging

Mixed fertilizer moves to packaging stations. Workers or machines fill standardized bags while printing essential product details: nutrient content, production date, and manufacturer information. Tight sealing prevents moisture absorption and caking.

- Quality Assurance and Storage

Final products undergo random sampling to verify nutrient levels and granule uniformity. Approved batches get stored in warehouses, ready for distribution to meet agricultural needs.

This streamlined NPK blending fertilizer production line process maintains strict quality control at every stage, delivering reliable fertilizers that support modern farming requirements.