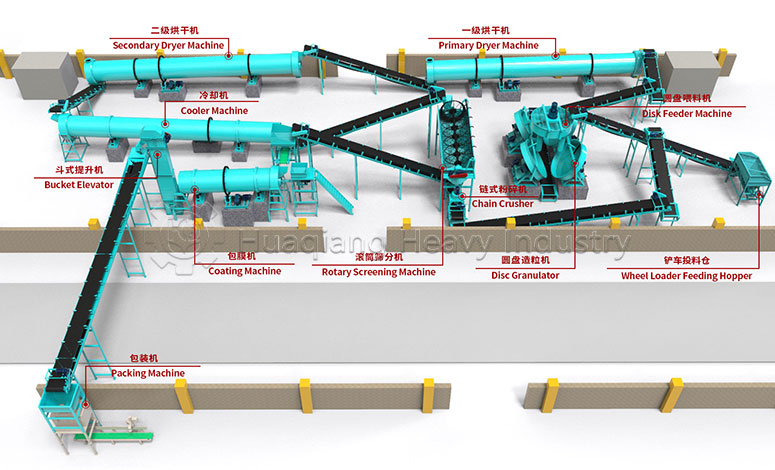

Daily maintenance guide for key equipment in bio-organic fertilizer production lines

For a bio-organic fertilizer production line to run efficiently, stable equipment operation is essential. Regular maintenance is key to ensuring productivity and extending equipment life. Here are the critical machines needing focused maintenance and key points:

1.Fermentation Turning Equipment

Check wear on compost turning machines blades. Regularly lubricate bearings and drive chains. Clean off stuck organic material to prevent corrosion.

2.Crusher

Regularly check blade sharpness. Clean screen blockages. Tighten bolts. Lubricate bearings. Prevent rust from material residue.

3.Mixer

Check wear on mixing paddles. Clean leftover material. Lubricate drive components. Ensure motors run normally.

4.Granulator

Check mold wear. Clean leftover pellets. Adjust the gap between rollers. Lubricate key parts.

5.Dryer and Cooler:

Clean heat exchangers. Check fan operation. Prevent material blockages. Regularly inspect temperature control systems.

6.Screener

Check screens for damage. Clear blockages. Adjust vibration motor balance. Lubricate bearings.

7.Packaging Machine

Clean metering devices. Check sealing parts. Lubricate the drive system. Calibrate load cells.

The stable operation of your bio-organic fertilizer production line depends on daily maintenance of this key equipment. Regular checks, cleaning, lubrication, and replacing wear parts will significantly reduce breakdowns, boost efficiency, extend equipment life, and ensure consistent fertilizer quality.