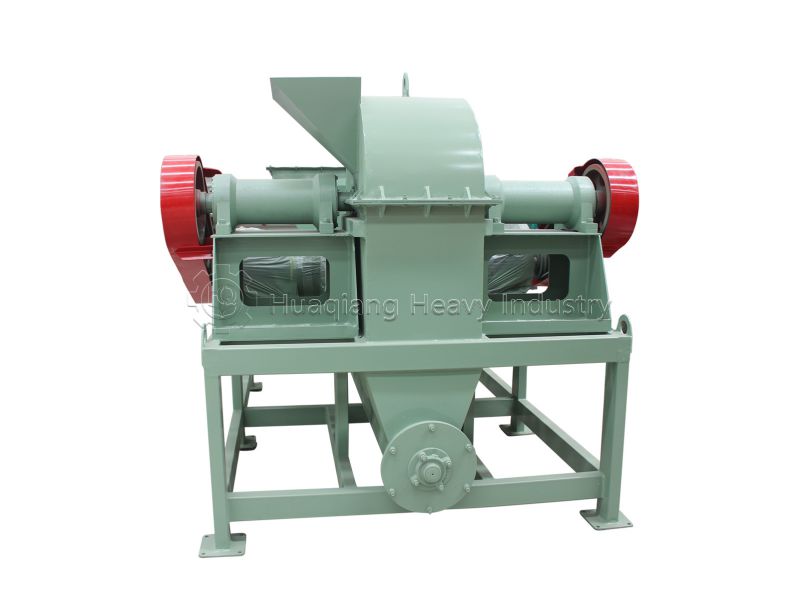

How fertilizer crushers improve quality and efficiency in organic fertilizer production?

In modern organic fertilizer production, fertilizer crushers have become essential equipment. Their efficient grinding capabilities positively impact the entire industry.

1.Raw Material Processing Efficiency

Modern fertilizer crushers use high-strength alloy blades and optimized designs to quickly handle various organic waste. They can process 5-10 tons of animal manure per hour. Crop straw can be ground to an adjustable fineness (1-5mm), and food waste achieves over 95% uniformity after crushing.

2.Improved Fermentation Efficiency

Crushed materials have a larger specific surface area, creating an ideal environment for microbial activity. This shortens the fermentation cycle by 40% (from 60 days to 35 days). Temperature distribution becomes more even, eliminating pathogens more thoroughly. Better oxygen penetration ensures more complete aerobic fermentation.

3.Higher-Quality Finished Product

Fine grinding significantly boosts fertilizer quality: nutrient release speeds up by 50%, and granule uniformity exceeds 90%.

4.Lower Production Costs

Using crushers cuts costs substantially: labor expenses drop by 70%, energy use falls by 30% (compared to traditional crushing methods), and raw material utilization rises to 98%.

5.Enhanced Environmental Benefits

Improved crushing technology offers dual environmental advantages: it reduces pollution caused by piled organic waste and lowers dust emissions during production.

Fertilizer crushers drive the industry toward large-scale, standardized, and efficient production. With new technologies like smart controls and energy-saving designs, these machines will keep powering sustainable organic farming.