The significant role of fertilizer screener machines in advancing bio-organic fertilizer production lines

In bio-organic fertilizer production lines, the fertilizer screener machine is a core piece of equipment. It directly affects the finished product’s uniformity, purity, and market competitiveness. Efficient screening not only optimizes the product structure but also increases the automation level of the production line, driving the organic fertilizer industry towards large-scale, standardized development.

1.Improves Finished Product Quality

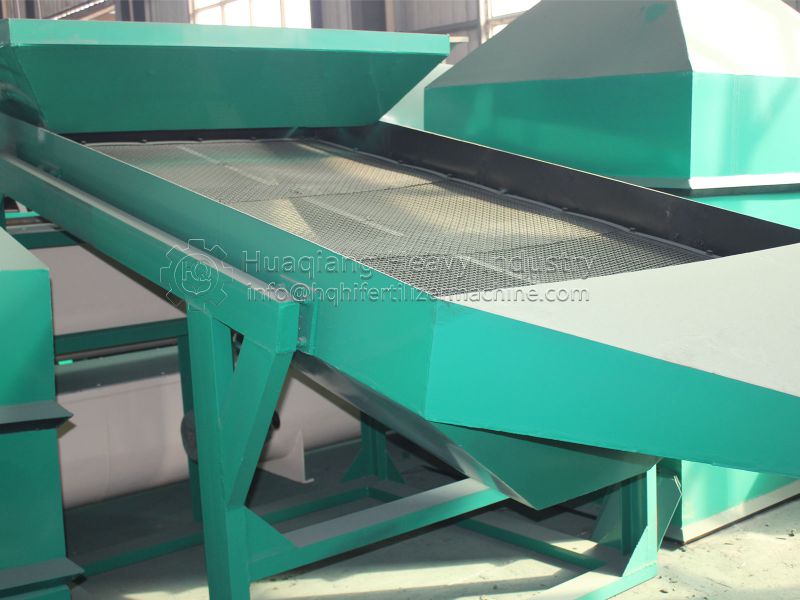

Screener machines use multi-layer vibrating screens to grade fermented organic raw materials by particle size, removing oversized particles and impurities. This ensures uniform, fine granules in the final product. It enhances the fertilizer’s appearance and optimizes its solubility and nutrient release rate, meeting the demands of high-end agriculture.

2.Reduces Return Rate

In traditional organic fertilizer production, unscreened, oversized particles need to be crushed and re-pelletized, increasing energy use and costs. Modern drum or vibration screener machines can precisely separate acceptable and oversized particles, reducing the return rate by over 30% and significantly boosting production efficiency.

3.Promotes Production Line Automation

Intelligent screener machines can connect with automatic packaging and conveying systems, enabling fully unmanned operation. This lowers labor costs while reducing human error, ensuring product consistency.

4.Drives Green Production

Efficient screening reduces dust emissions. Combined with enclosed designs, it minimizes environmental pollution during production, aligning with modern environmental policies and supporting sustainable business growth.

The fertilizer screener machine is not just a key piece of equipment in bio-organic fertilizer production; it’s a vital force driving the industry towards higher quality and efficiency.