Balancing efficiency and environmental needs in NPK blending fertilizer production lines

Against a backdrop of rising agricultural demands and stricter environmental rules, finding the balance between efficiency and eco-standards in NPK blending fertilizer production lines have become a key industry focus. By refining production methods and equipment setup, it’s entirely possible to achieve both high efficiency and green manufacturing.

1.Better Raw Material Management

Use enclosed raw material storage to cut down dust leaks.

Adopt precise batching technology, keeping errors within ±1%.

Apply low-dust pretreatment processes, reducing dust emissions by 30%.

2.Upgraded Production Processes

Install high-efficiency dust removal systems that capture up to 99% of dust.

Use low-energy mixing equipment, cutting unit energy use by 15–20%.

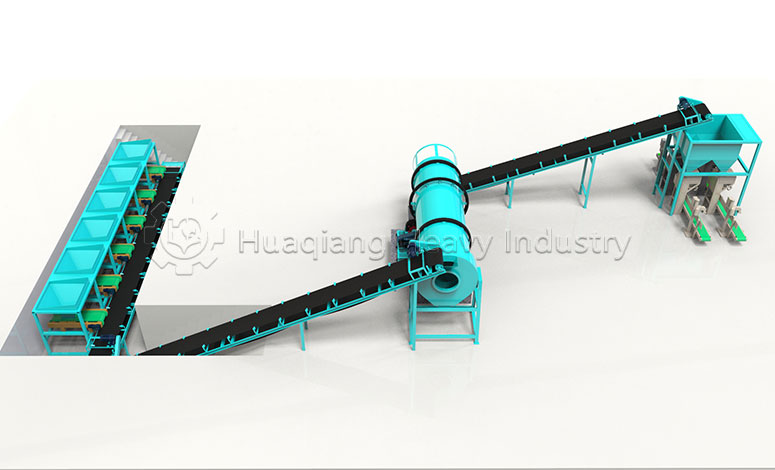

Optimize NPK blending fertilizer production line layout to shorten material transport distances and save energy.

3.Smart Control Systems

Monitor energy use in real time using IoT technology.

Build data analytics platforms to fine-tune production parameters.

Enable automatic alerts and responses for abnormal emissions.

4.Resource Recycling

Reuse collected dust, achieving 99.5% raw material utilization.

Centralize and fully recycle packaging waste (100% recovery).

Install waste heat recovery systems, boosting thermal efficiency by 25%.

In short—through tech innovation and scientific management—NPK blending fertilizer production lines can absolutely meet the goal of efficient, clean, low-carbon production.