Wet and dry granulation: Choosing the best process for your organic fertilizer production line

In modern organic fertilizer production lines, the granulation process is key to product quality and efficiency. Wet and dry granulation each have their own strengths and best uses.

1.How They Work Differently

Wet Granulation needs liquid (usually water or an organic solution) added as a binder. This step requires drying afterwards to remove the extra moisture. Dry Granulation relies only on mechanical pressure, with no liquid binder added. This skips the drying step completely.

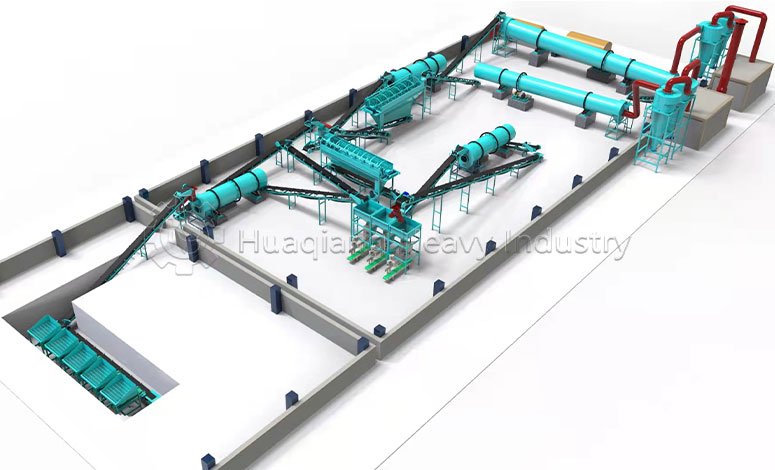

2.Equipment Setup Comparison

A wet granulation organic fertilizer production line usually involves more complex equipment. Dry granulation simplifies the process, needs less space, and uses less energy.

3.Differences in the Final Product

Wet granulation makes smooth, round granules that are strong, resist breaking, and dissolve at a moderate rate. Dry granulation produces denser, irregularly shaped granules. These dissolve slower, but release nutrients over a longer period.

4.Suitability for Different Raw Materials

Wet granulation needs strict control over raw material moisture (usually 20%-30%). It works best with materials high in organic matter or fiber. Dry granulation handles drier raw materials (10%-15% moisture) better. It’s especially good for dry organic waste or mixes with mineral materials, but requires finer raw material particles.

5.Investment and Operation Costs

Wet granulation lines cost more upfront and use more energy (especially for drying), but produce a better-looking product. Dry granulation equipment is cheaper to buy, uses less energy, and is simpler to maintain, but the final granules look rougher.

Choosing between wet and dry granulation for your organic fertilizer production line depends on your raw materials, the product you want to make, and your budget. Technological advancements are leading to new hybrid approaches, offering more efficient solutions for organic fertilizer production.