Comparison of granulation processes between disc granulator and flat die granulator

In fertilizer, feed, and chemical industries for granule production, disc granulators and flat die granulators are two common machines. Both turn powder into granules, but they differ significantly in how they work, where they’re used, and the final product they make.

1.How They Work

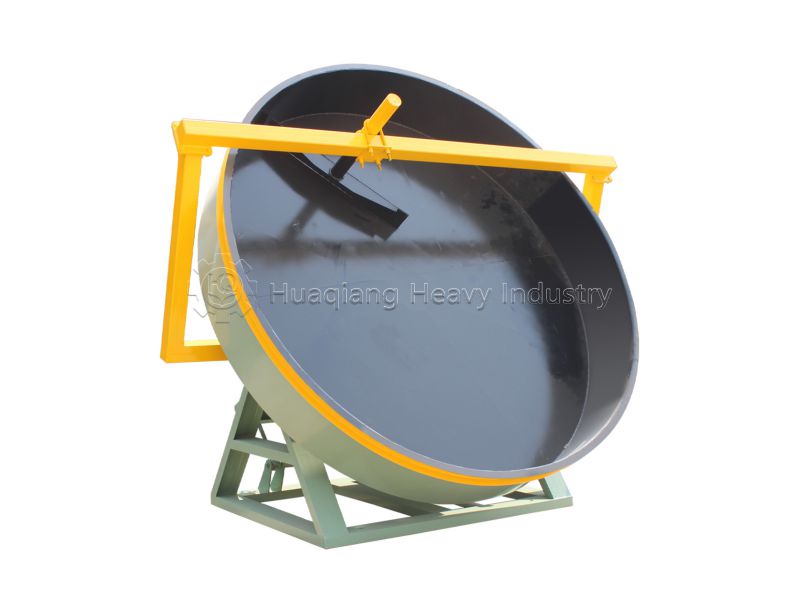

Disc Granulator: Uses a tilted, rotating disc. Material rolls and sticks together under centrifugal force and gravity, forming round balls as binder is sprayed on.

Flat Die Granulator: Uses vertical pressure. Material is squeezed through holes in a flat die by rollers to form shaped granules.

2.Where They Fit Best

Disc Granulator: Good for organic fertilizer or bio-organic fertilizer needing round balls. Works best with stickier materials and flexible small-scale production.

Flat Die Granulator: Suited for feed or compound fertilizer needing dense granules. Handles low-stick powders well and is built for steady, high-volume runs.

3.Cost and Maintenance

Disc granulators are simpler, easier to maintain, and typically cost 30%-40% less upfront. However, flat die granulators make more consistent granules with higher yields (as high as 98%+), which can mean better long-term value.

4.Flexibility

Disc granulators handle recipe changes easily – good for making small batches of different mixes. Flat die granulators need die changes to adjust granule size and are better for large runs of fixed recipes.

In short, choosing between them depends on your material, product needs, and production scale.