Building a multi-functional bio-organic fertilizer production line: From raw materials to high-value products

With the rapid development of eco-friendly agriculture today, establishing a bio-organic fertilizer production line has become a crucial way to recycle agricultural waste and improve soil. A complete production line not only transforms organic waste like livestock manure and crop straw into valuable products, but also produces high-value bio-organic fertilizer. This fertilizer offers multiple functions including soil improvement, nutrient supply, and biological control.

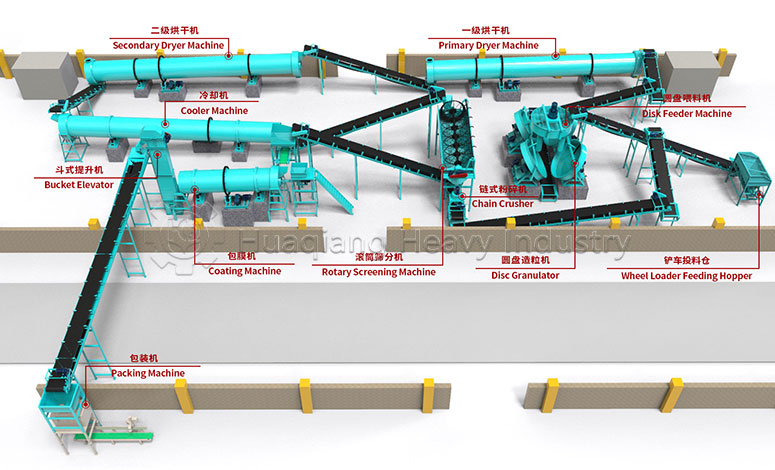

Core Processes and Equipment Setup

1.Raw Material Pre-treatment System

Uses heavy-duty shredders to process coarse fiber materials like straw. Employs solid-liquid separators to reduce moisture in livestock manure below 60%. Utilizes automatic batching systems to precisely control the carbon-to-nitrogen ratio at 25-30:1.

2.Efficient Fermentation System

Uses trough-type compost turning machines or windrow composting methods. Maintains a high-temperature phase (55-65°C) for 7-10 days with smart temperature control. Adds functional microbial consortia (like phosphate-solubilizing, potassium-releasing, nitrogen-fixing bacteria).

3.Refined Processing System

Grinds fermented material below 3mm using specialized crushers. Offers multi-functional granulators (disc, flat-die, or rotary drum granulators types).Employs low-temperature drying systems (≤80°C) to protect the activity of functional microbes.

Key Technologies for Multi-functional Bio-organic Fertilizer Production

1.Functional Microbe Blending: Scientifically combines different functional microbial strains.

2.Nutrient Slow-release: Adds natural slow-release materials like humic acid.

3.Soil Conditioning: Incorporates mineral amendments to adjust pH.

4.Biological Control: Adds antagonistic microbes to prevent soil-borne diseases.

As organic agriculture grows rapidly, demand for multi-functional bio-organic fertilizer is also rising fast, showing broad market prospects.