NPK blending machines: The unsung hero of high-efficiency fertilizers

In modern fertilizer production, the NPK blending machine plays a crucial role. It is not only the core equipment of the NPK blending fertilizer production line but also a key factor determining the final fertilizer quality.

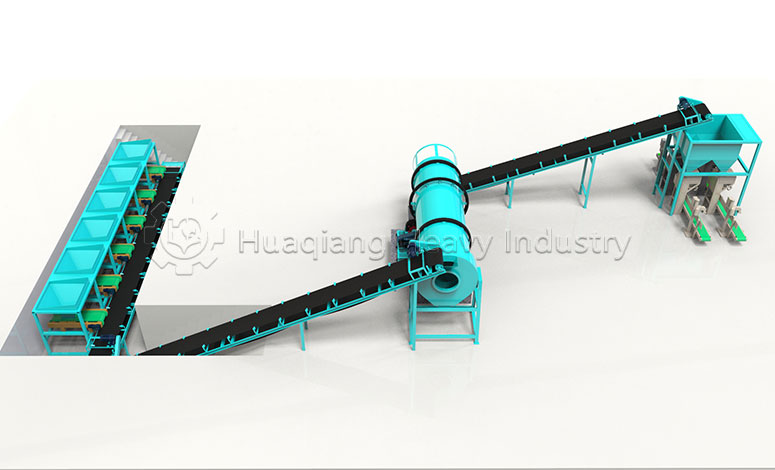

A typical NPK blending fertilizer production line constitutes a complete system from raw material input to finished product packaging. In this system, the fertilizer mixer machine, with its unique design and efficient operation, ensures the uniform distribution of various nutrients. Its rational structural design enables nitrogen, phosphorus, potassium, and trace elements to achieve ideal mixing effects in a short time.

The advantages of this specialized mixing equipment are obvious. It can handle raw materials in different forms, whether granular or powdered, achieving thorough mixing. The unique internal stirring device, through scientific movement, causes convection and diffusion of materials within the container, avoiding stratification or segregation.

In practical applications, the performance of the fertilizer mixer machine directly affects the efficiency of the entire production line. Its stable operation ensures production continuity, while the uniform mixing effect lays a good foundation for subsequent processes. This not only improves product quality but also optimizes production efficiency.

With the continuous improvement of agricultural demands, NPK blending machines and the blending fertilizer production lines they are used in are developing towards greater intelligence and precision. These specialized machines, through continuous optimization, consistently provide reliable support for agricultural production.