Factors affecting pelletization rate in disc granulators and optimization strategies

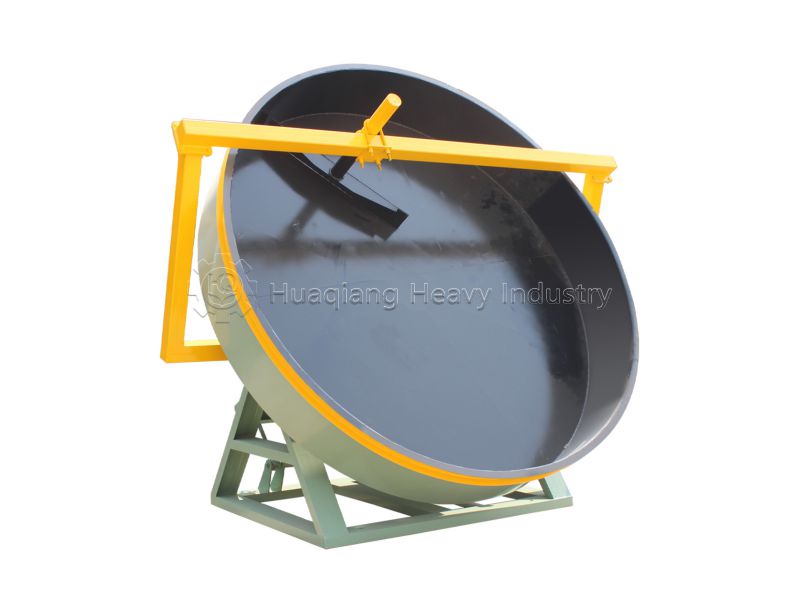

Disc granulators are key equipment for making pellets in industries like fertilizer and feed. The pelletization rate directly impacts production efficiency, raw material usage, and product quality.

1.Raw Material Properties

Particle Size: Coarse particles lead to loose, poorly formed pellets and lower rates. Optimal fineness (80-200 mesh) improves binding.

Moisture Content: Too little moisture (<10%) makes shaping difficult. Too much (>20%) causes sticking. The best range is usually 12%-18%.

Binding Properties: Materials with poor stickiness (like phosphate rock powder) need binders like bentonite or starch added to improve pellet formation.

2.Equipment Parameter Settings

Disc Tilt Angle: The angle of the disc granulator is too large (>55°), the material rolls too fast, and the particles are not dense. Too shallow (<40°) lets material sit too long, causing clumping. Recommended: 45°-50°.

Rotation Speed: Too fast breaks pellets easily. Too slow reduces pellet formation speed. Generally control between 15-35 rpm, adjusting based on the material.

Scraper Position: Too high off the disc bottom causes material buildup. Too low causes excessive wear. Maintain a proper gap (5-10mm).

3.Operational Process Factors

Uniform Feeding: Uneven or interrupted feeding creates inconsistent pellet sizes. Steady material supply is needed.

Spray System: Poor atomization causes uneven wetting (some spots too wet, others too dry), hurting pellet quality. Nozzles need regular checks.

Return Fines Ratio: Adding some fines back (20%-30%) helps use fine powder efficiently. But too much weakens pellet strength.

In short, boosting the pelletization rate in disc granulators requires looking at the material, machine settings, the process, and the surroundings. This ensures high pellet yield and quality.