Factors affecting production capacity of NPK blending fertilizer production lines

The production capacity of NPK blending fertilizer production lines is limited by multiple factors. Understanding these factors is crucial for improving efficiency.

- Equipment Performance

Accuracy and speed of dosing systems: Precise dosing equipment ensures fast and accurate distribution of N, P, K, and other raw materials in preset ratios. Low-precision equipment risks formula errors, requiring rework that slows production. Slow dosing directly reduces hourly output.

- Production Processes

Different technologies impact capacity. Advanced methods like the ammonia-acid process or controlled-release production techniques boost nutrient content and efficiency, increasing overall output.

- Raw Material Properties

Particle size: Large variations in particle size cause segregation or clogging during mixing. Fine powders may clump, reducing material flow and leading to inaccurate dosing or uneven blending.

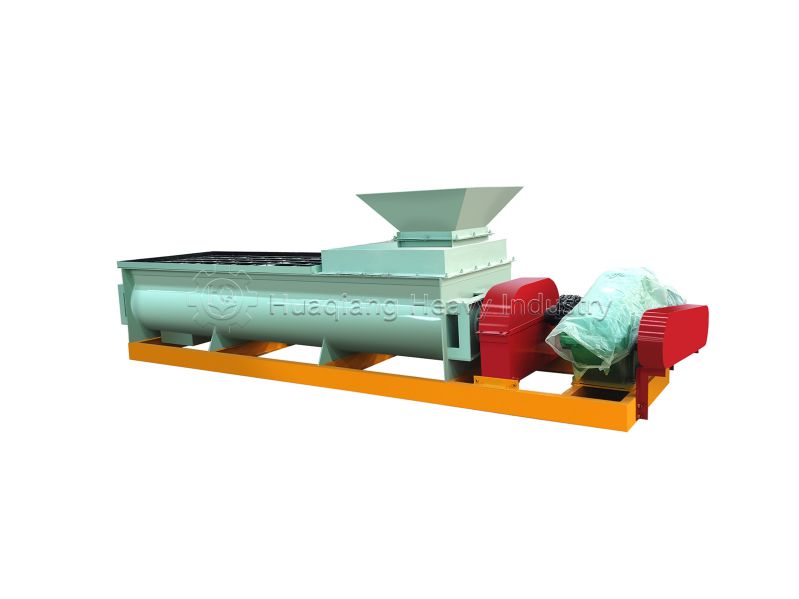

Moisture content: Overly damp materials tend to cake, causing jams in conveyors and fertilizer mixer machines. This lowers equipment efficiency, increases downtime, and reduces actual operating hours.

- Operations Management

Production planning: Smart scheduling keeps equipment running at full capacity without overloading. Effective coordination resolves equipment breakdowns and material shortages promptly, maintaining stable production.

In summary, the output of NPK blending fertilizer production lines depends on equipment quality, production methods, raw material characteristics, and operational practices. Manufacturers should select suitable technologies and workflows based on their specific needs to optimize both production capacity and product quality.