How to build a small organic fertilizer production line?

With growing environmental awareness, setting up a small organic fertilizer production line offers a practical solution for managing organic waste while generating economic benefits. Here’s a straightforward guide to building one:

- Site Planning

Location: Choose a site with easy transportation access and sufficient distance from residential areas to minimize odor impact. A flat, well-drained area is ideal.

Space: A compact space of 500–1,000 square meters is usually enough. Divide the area into functional zones: raw material storage, processing area, fermentation zone, and finished product storage.

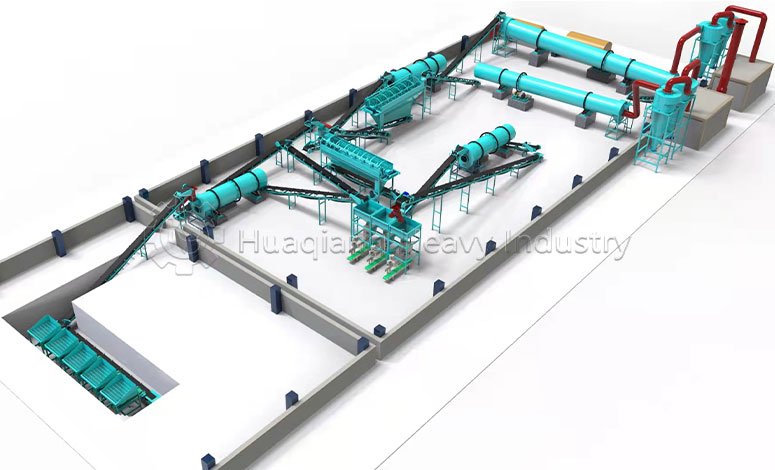

- Equipment Selection

Crushing Equipment: Use a small cage crusher to break down materials like crop stalks or manure into fine particles for easier processing.

Fermentation Equipment: Opt for low-cost trough fermentation systems, which are simple to operate and suitable for small-scale production.

Granulation Equipment: A disc granulator or flat-die granulator can shape the fermented material into uniform granules.

Drying and Cooling: A drum fertilizer dryer and cooler help reduce moisture and stabilize the fertilizer.

Screening and Packing: Use a drum screener machine to filter out irregular particles, followed by an automatic packing machine for bagging.

- Production Process Design

Raw Material Collection and Prep: Gather organic waste (such as livestock manure, crop residues) mix and crush them to ensure uniformity.

Fermentation: Add microbial agents to the mix, control moisture and temperature in the fermentation system, and let it decompose naturally. This step usually takes 15–30 days.

Granulation, Drying and Cooling: Shape the fermented material into pellets, dry them to ≤15% moisture, then cool to room temperature.

Screening and Packing: Remove substandard particles, then pack the final product for sale.

- Operations Management

Staff Training: Train workers on equipment operation, safety protocols, and quality standards.

Quality Control: Regularly test the fertilizer’s nutrient content, moisture, and pH to meet industry standards.

Marketing: Promote the product through local farming networks, agricultural fairs, or online platforms. Highlight eco-friendly benefits and cost savings for crops.