Comparative analysis of the core parameters of rotary drum granulator and disc granulator

For making organic fertilizer, rotary drum granulators and disc granulators are the two main types of equipment. But their design, output, and best uses are quite different.

1.Capacity Comparison

Rotary Drum Granulator: Uses a rotating drum for continuous granulation. Typical capacity is 5-20 tons per hour. Best for large-scale production in medium to big fertilizer plants.

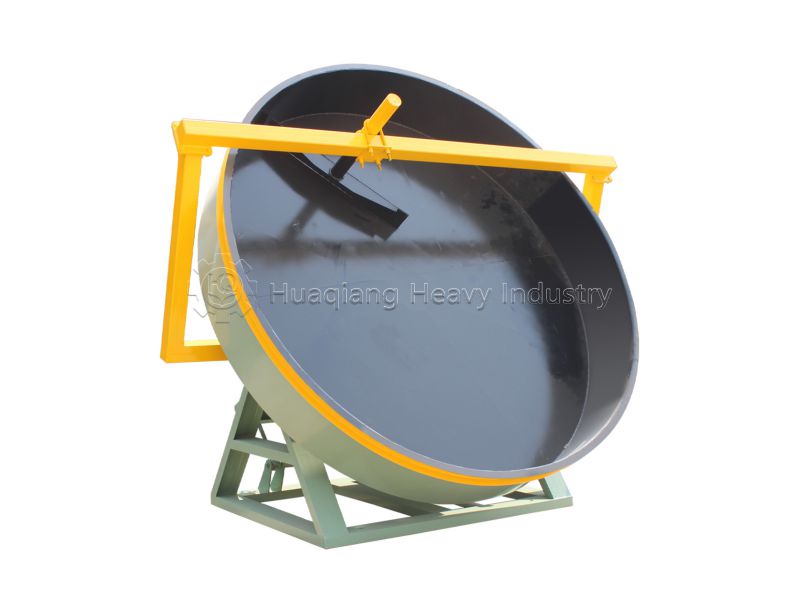

Disc Granulator: Forms granules by rolling material on a tilted disc. Capacity is usually 1-5 tons per hour. Better suited for smaller production lines or testing.

2.Particle Quality Comparison

Uniformity: Rotary drum granulators make more regular, rounder particles (2-8mm size). They achieve a yield rate of 95% or more. Disc granulator particles are less uniform and often need sieving later.

Strength: Because of the longer rolling and squeezing time in the drum, the granules are stronger and resist breaking during transport.

3.Energy Use andRunning Costs

Rotary Drum Granulator: Needs a bigger motor but uses less energy per ton produced. More cost-effective for long-term, continuous operation.

Disc Granulator: Uses a smaller motor, but energy use per ton is higher. Fits better with batch production.

4.Material Suitability andMaintenance

Material Handling: Rotary drum granulators can handle wetter, high-fiber materials like manure or sludge. Disc granulators need drier material (moisture ≤30%).

Maintenance Cost: Rotary drum granulators have a more complex structure and need more frequent maintenance. Disc granulators are simpler and break down less often.

In short, both machines have their strengths. The right choice depends on your production scale, raw materials, and budget.