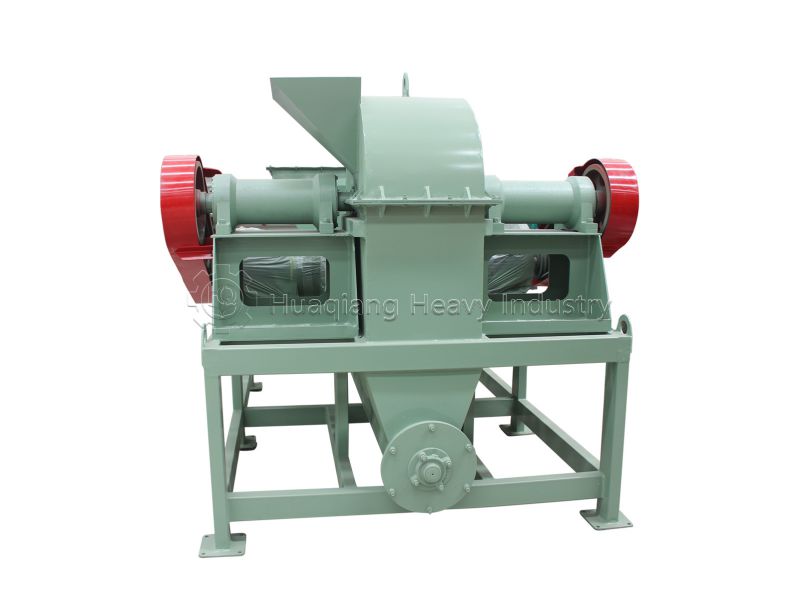

Common cage crusher failures and solutions in production

In industrial production, stable operation of cage crushers is crucial. However, they are not immune to malfunctions that can affect production efficiency.

Excessive vibration is a common malfunction of cage crushers. Abnormal vibration occurs when the rotor is unbalanced. In this case, shut down the machine and use a steel brush or scraper to remove any adhering material from the rotor bars and end plates, paying particular attention to any buildup within the gaps between the bars. Bearing damage can also cause vibration. For example, poor lubrication and failure to relubricate regularly (usually every 200 hours) can damage the bearings and cause vibration. If bearing damage is confirmed, replacement is necessary.

Severe noise should not be ignored. A loose or detached striker will produce a high-frequency “clattering” sound accompanied by slight vibration. In this case, turn off the power, open the inspection window, and manually move the striker. If it shakes by more than 5mm, or if the striker mounting bolts are loose or missing, the fault has been located.

Belt slippage is also common. If the belt tension is insufficient, stop the machine and manually press the belt. If deflection exceeds 15mm (normal is 5-10mm), adjust the motor base bolts and move the motor backward to increase belt tension. If there is no room for adjustment in the base, replace with a longer belt. If the pulleys are misaligned or worn, observe that they are not aligned and the grooves are widened. In this case, loosen the pulley fixing bolts, align them with a level, and replace with a pulley of the same model.

When a cage crusher malfunctions, we must calmly analyze the situation, troubleshoot, and resolve it correctly. We must also regularly maintain the equipment to reduce the likelihood of malfunctions and ensure smooth production.