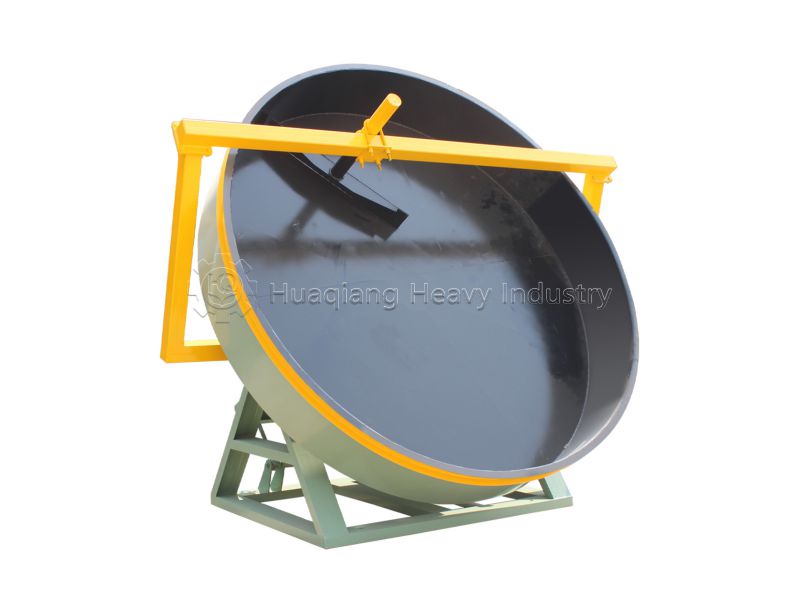

Disc Granulators: Process advantages over other granulation methods

In fertilizer production, disc granulators have become the preferred choice for many manufacturers due to their unique granulation principle and process characteristics. Compared to other methods like extrusion granulation or spray granulation, disc granulators offer clear technical advantages in several areas, leading to higher economic benefits and better product quality.

1.High Sphericity

Material undergoes complex motion (rolling, sliding, falling) in the tilted disc, producing granules with sphericity exceeding 0.8. This is far superior to extrusion granulation products and is particularly suitable for high-grade fertilizers.

2.Excellent Granulation Rate

By adjusting the disc angle, rotation speed, and spray water volume, granulation rates of 85%-95% can be achieved. The return ratio is kept below 15%, significantly improving raw material utilization.

3.Strong Formulation Adaptability

Capable of processing various formulations like organic-inorganic compounds, bio-fertilizers, and microelement fertilizers. They are especially well-suited for granulating mixtures containing fibrous organic matter.

4.Simple and Low-Cost Maintenance

With no complex internal structure and few maintenance points, daily maintenance only involves checking bearings and the gear reducer. Annual maintenance costs are about 40% lower than those for rotary drum granulators.

Thanks to their combined strengths of producing high-quality pellets, simple operation, and lower investment, disc granulators remain a classic choice in fertilizer granulation processes. Whether setting up a new production line or upgrading an existing one, disc granulators deliver significant economic benefits and improved product quality for manufacturers.