How to choose the right bio-organic fertilizer production line based on farm size?

When turning livestock manure into a resource, picking the right bio-organic fertilizer production line needs to perfectly match the farm’s scale. Farms with different herd sizes have very different manure handling needs, budgets, and ways of operating.

1.Small Farms

Recommended Setup: Simple trough fermentation line (Investment: ¥150,000 – ¥250,000)

Capacity: 3-5 tons/day

Key Equipment: Small windrow compost turning machine (1.5m wide), combined crusher and screener, manual packaging station.

Benefits: Needs only about 300 sqm of space, can flexibly handle mixtures like pig or chicken manure.

2.Medium Farms

Recommended Setup: Semi-automatic fermentation line (Investment: ¥500,000 – ¥800,000)

Capacity: 10-20 tons/day

Upgrades: Intelligent turner (with temperature sensors), automatic batching system, disc granulator set, mobile packaging machine.

Cost-Effectiveness: Processing cost per ton is 40% lower than small lines. Can also handle manure from nearby farms.

3.Large Farming Groups

Recommended Setup: Smart factory-style production line (Investment: ¥2 million+)

Capacity: 50-100 tons/day

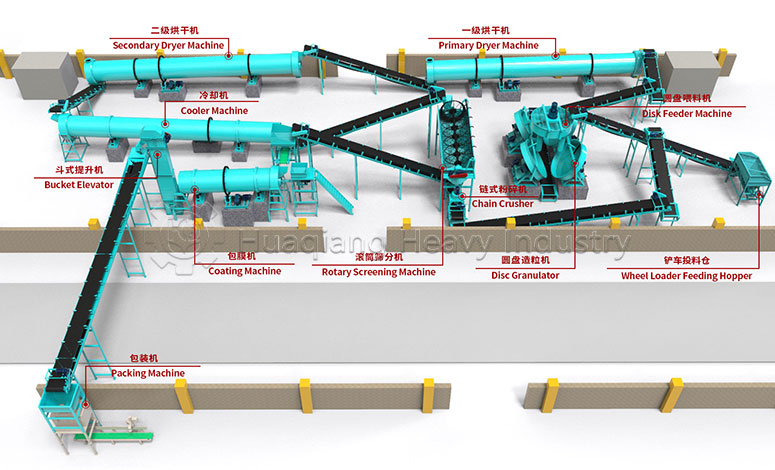

Advanced Features: Fully enclosed fermentation workshop (with bio-deodorization), computer-controlled turner, extrusion granulator + coating machine, automated palletizing and storage system.

Always choose a production line with slightly more capacity than your current manure output, leaving about 20% room for growth. Getting the right equipment can turn manure handling from a cost center into a profit center.