How to choose the right fertilizer granulator for your NPK blending fertilizer production line?

In NPK blending fertilizer production line, the granulator is key. It directly affects fertilizer granule quality, production efficiency, and your product’s market edge. A good granulator mixes NPK materials evenly and forms strong, uniform granules. This boosts the fertilizer’s physical properties and how well it works in the field.

1.Matching Material Properties

Different NPK blends vary in stickiness and moisture. Choose your machine accordingly: Disc granulators handle less sticky materials well. Rotary drum granulators work better for sticky mixes.

2.Meeting Production Needs

Pick the size based on your daily output: Small lines (1-5 tons/hour): Flat die granulators.Medium lines (5-20 tons/hour): Rotary drum granulators. Large lines (20+ tons/hour): Double roller press granulators.

3.Granule Quality Requirements

Disc granulators give the most uniform particles. Press granulators make the densest granules. Choose based on the specs you need.

4.Energy Use andMaintenance Costs

Newer, efficient granulators cost more upfront but save energy long-term—cutting use by over 30%.

5.Environmental Performance

Modern granulators should include dust collection and exhaust treatment to meet strict environmental rules.

NPK Fertilizer Granulator Types Compared

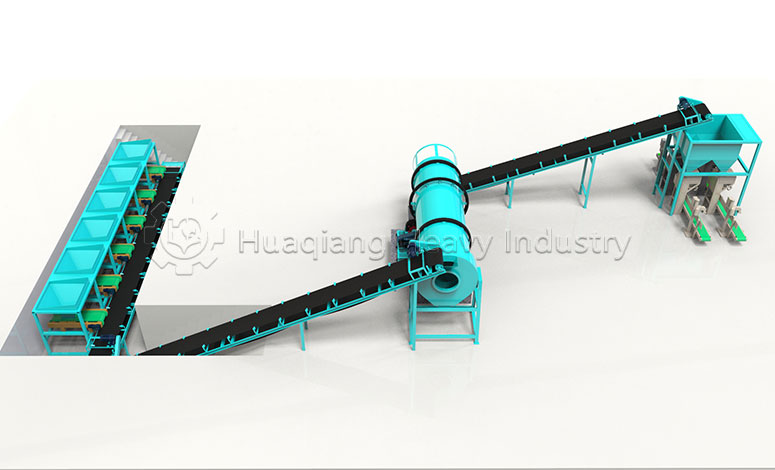

1.Rotary Drum Granulator: High capacity, versatile. Best for medium or large NPK lines.

2.Disc Granulator: Uniform granules. Ideal for small/medium high-quality production.

3.Double Roller Press Granulator: Eliminates drying, saves energy. Great for high-concentration blends.

When picking a granulator for NPK blending, weigh all these factors. A good supplier offers full support—process design, setup, training—to keep your line running smoothly.