Guide to selecting key equipment for bio-organic fertilizer production lines

With the rapid growth of green agriculture and organic farming, bio-organic fertilizer production lines are becoming a popular choice in the fertilizer industry. However, the core of a production line lies in equipment selection.

1.Fermentation Equipment

Trough Compost Turner: Best for large-scale production. Ensures even turning and high fermentation efficiency.

Crawler-type Turner: Ideal for windrow composting. Offers flexibility and lower investment.

Closed Fermentation Tank: Highly automated, prevents odor leakage, and excels in eco-friendliness.

Selection Tip: Choose based on raw materials (like livestock manure, straw) and production scale. Ensure thorough composting to eliminate pathogens and weed seeds.

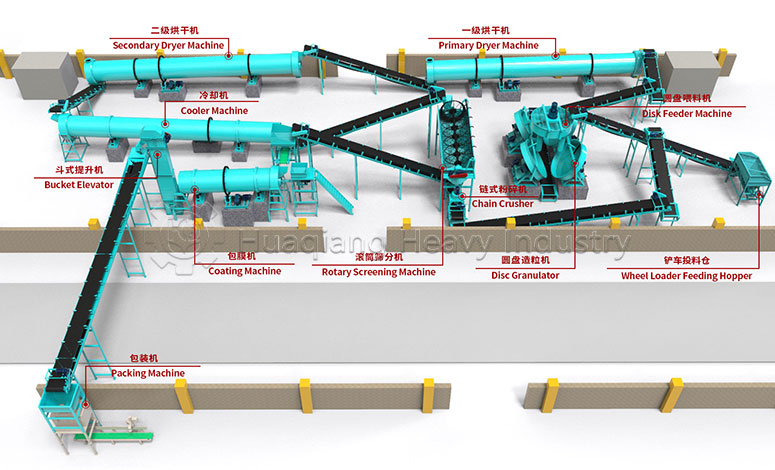

2.Crushing Equipment

Half-Wet Material Crusher: Handles high-moisture organic materials well. Prevents clogging and boosts efficiency.

Chain Crusher: Suitable for fibrous materials (like straw, mushroom residue).

Selection Tip: Consider material moisture and hardness. Aim for uniform particle size to improve mixing and granulation later.

3.Mixing Equipment

Double Shafts Paddle Mixer: Delivers high mixing uniformity for powders and granules.

Ribbon Mixer: Works well with sticky materials and mixes thoroughly.

Selection Tip: Opt for corrosion-resistant materials (like stainless steel) to avoid material sticking and improve efficiency.

4.Granulation Equipment

Disc Granulator: Fits small-to-medium production. Produces rounded, moderately strong granules.

Rotary Drum Granulator: High-capacity, ideal for large-scale continuous production.

Extrusion Granulator: Energy-efficient and good for high-density organic fertilizer shaping.

Selection Tip: Select based on market needs (granule size or hardness). Ensure finished products resist breakage for easy transport and application.

Choosing the right equipment for production line boosts efficiency and guarantees product quality—supporting the growth of green agriculture.